-40%

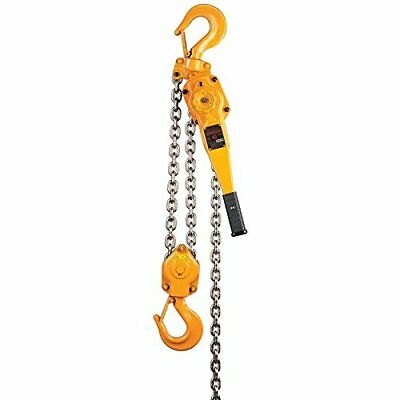

Harrington LB Lever Hoist, Hook Mount, 2-3/4 Ton Capacity, 10' Lift

$ 356.4

- Description

- Size Guide

Description

Harrington LB Lever Hoist, Hook Mount, 2-3/4 Ton Capacity, 10' LiftLoad Capacity:5500 pounds | Pull Force:81 Pounds | Headroom String:14.8 Inches

| Lever length:10.4 inches | Hook Opening String:1.4 Inches | Maximum lifting

height:10 Feet The Harrington LB lever hoist with hook mount is a compact,

manually operated hoist with all steel construction for strength; and low

headroom, a handle with 360-degree rotation and 15-degree recovery strokes,

and mount and load hooks with 360 degree rotations for work in small spaces

and at any angle. This hoist has a spring-loaded freewheel to facilitate rapid

adjustment of the load chain with one hand, and helps prevent accidental

freewheeling when a load is on the chain. The Weston-style brake has two

moisture-resistant brake pads, four braking surfaces, and two brake pawls to

help ensure reliability. The brake is completely covered for protection from

dirt and moisture. The forged, heat-treated alloy steel mount hook and load

hook resist fracture under stress. The mount hook is a pivot and swivel hook

for use with rigging applications. The grade 100 heat-treated load chain is

nickel-plated and corrosion resistant. This hoist also has a rubber handle

grip for non-slip operation, and machined, heat-treated, split load double

reduction gears for durability. The Harrington LB lever hoist is typically

used in construction, mining, manufacturing, and shipbuilding applications,

but can be employed for similar purposes in other industries. This hoist is

factory load tested to 125% of rated load capacity in accordance with American

National Standards Institute/American Society for Mechanical Engineers

(ANSI/ASME) requirements. It also complies with ANSI/ASME B30.21 and ANSI/ASME

HST-3M standards. When used according to manufacturer’s recommendations, this

product is covered by a two-year warranty from date of shipment against

defects in workmanship or materials. Hoists are devices that use relatively

small amounts of force to lift, lower, and move heavy loads. Manual hoists

transfer a small, hand-exerted force across a series of gears or pulleys that

multiply the force into one large enough to lift the designated load. This

makes it possible for an operator to manage heavy loads. The manual force is

usually applied using a hand chain, lever, or ratchet pulley, lifting the load

by a hook attached to a chain, rope, or wire. Many manual hoists use disk

brakes called Weston-style brakes that hold the load in place while the

operator’s hands are released to make the next pull, secure the load once it

has been lifted, and control the descent of the load as it is lowered. Manual

hoists also may use ratchets instead of brakes to secure and control the load.

Hoists are commonly suspended from structures by hook or trolley mounts, and

used in a variety of industries including transportation, construction,

manufacturing, mining, plumbing, foundry, and material handling. Load capacity

is the maximum rated load a hoist can handle. While manufacturers may indicate

they have tested a hoist beyond its limits, operators should never attempt to

lift a load heavier than the maximum rated load capacity. Pull force describes

the amount of force that needs to be applied to lift a load. If a 1/2 ton

manual hoist specifies a pull force of 40 lbs., for example, the operator

needs to be able to pull a 40 lb. weight in order to lift the maximum 1/2 ton

(500 lb.) load. Headroom is the distance from the bottom of the load hook to

the top of the hoist. This is the minimum amount of vertical space needed for

the hoist to hang freely and operate correctly. Lift is the maximum vertical

distance the load hook can move a load. Harrington Hoists manufactures hoists

and cranes. The company, founded in 1854 and headquartered in Manheim, PA,

meets International Organization for Standardization (ISO) standard 9001.

Product Details

Brand

HARRINGTON

Product Type

Lever Hoists

Mpn

LB028-10

Compact manual lever hoist and hook mount with all-steel construction for strength; low headroom for work in small spaces and at any angle

Spring-loaded freewheel facilitates rapid adjustment of load chain with one hand, and helps prevent accidental freewheeling when a load is on the chain

Mechanical brake with two moisture-resistant brake pads, four braking surfaces, and two brake pawls to help ensure reliability

Factory load tested to 125% of rated capacity in accordance with ANSI/ASME requirements

Complies with ANSI/ASME B30.21 and ANSI/ASME HST-3M standards

-

Powered by